RE-ENGINEERING THE OPERATIONS PLANNING

In 2017, the Automation products factory was struggling with the high inventory level in the warehouses and WIP in the production lines, which was generating a high value of Cost of poor quality.

The management department was looking to reshape the operations management with the redesign of the production line, and specifically requested to enhance the implementation of SAP Production planning Module.

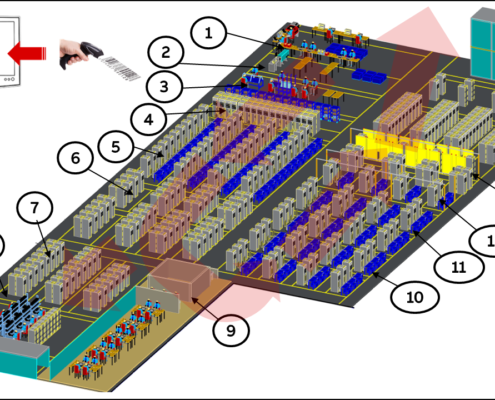

The project took around 6 months to redesign the production line with the creation of continuous flow production work centers, and the full control of the operations through the SAP Production Planning and Materials Master modules.

The major changes resulted in more control on the operations expenses, with a huge reduction in the under absorption costs. In addition to the 25% reduction in the utilization of factory area, due to the optimized design of the new production line.

Moreover, there was a remarkable reduction in the cycle time of the assembly operations with about 30% reduction in the inventory and WIP.

In addition to all of that, a higher improvement in the quality efficiency, was monitored through the Sigma Score from 1.1 to 2.6, which led in increasing the level of customer satisfaction.