REDESIGN AND CONSTRUCTION OF MOBILE ELECTRICAL UNITS PRODUCTION LINE

In 2015, the factory received an order with high a value of revenue, and an aggressive plan of delivery. The order couldn’t be refused for to its high positive impact on the business performance.

The factory capacity was far away from the delivery target dates, and there was a need to find a quick solution to manufacture and deliver the project deliveries on time.

Noting that the mobile electrical units used to be built in an open area, subjected directly to the sun light with a high temperature degree, and it was totally prohibited by the HSE department to work under these tough weather conditions.

Two major solutions were proposed, either to lease an external factory with wider enclosed area and build the Mobile electrical units there, or constructing a new hanger in the opened areas beside the factory.

The management department was not encouraged to lease an external factory, and they preferred to go to the second solution.

In fact there was no enough time for heavy construction, and the project team decided to build two hangers made from Steel structure and covered by PVC. This idea was well appreciated and acknowledged by the management department, due to its shorter time in fabrication and installation.

It took around one month, and the production line was ready for work.

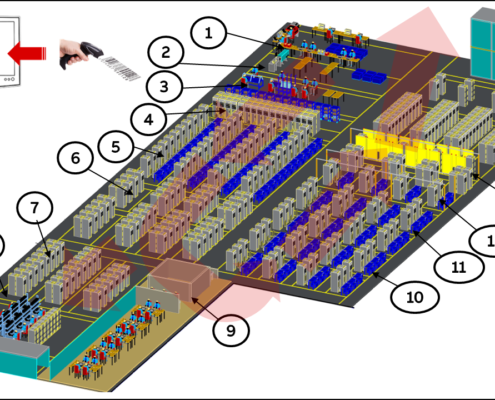

In addition to the implementation of the takt time concepts and balancing the production activities times, the factory could dramatically increase its capacity and deliver the products on time.